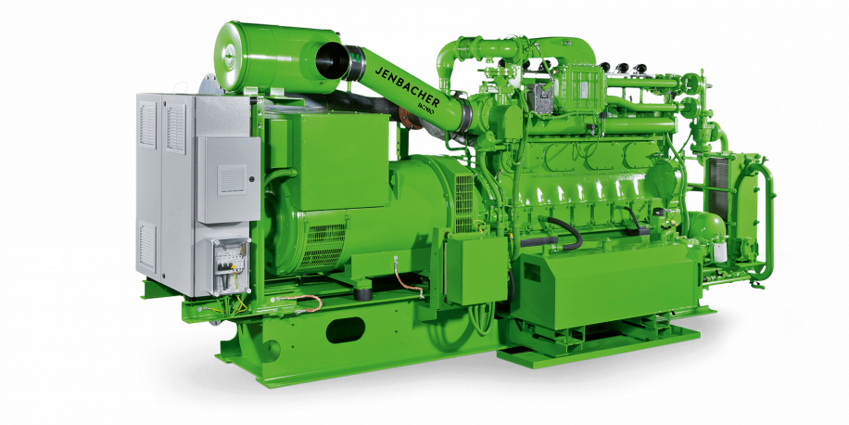

Introduced in 1976, INNIO’s Jenbacher Type 2 gas engine offers high-efficiency power with a robust design. The stationary engine concept provides excellent durability, while enhanced components and a proven control and monitoring model give the Type 2 engine outstanding reliability.

JENBACHER TYPE 2

With their durability, reliability, and fuel flexibility, Jenbacher Type 2 gas engines have an unmatched worldwide reputation of getting the job done.

They feature a high-performance, long-life spark plug for reliable operation, and applicable heat sources include engine cooling water, oil, mixture gas, and exhaust gas.

Applicable gas types include:

- Natural gas

- Associated petroleum gas (flare gas)

- Propane

- Biogas

- Sewage gas

- Landfill gas

- Coal mine gas

- Other special gases (e.g. coke, wood, and pyrolysis gases)

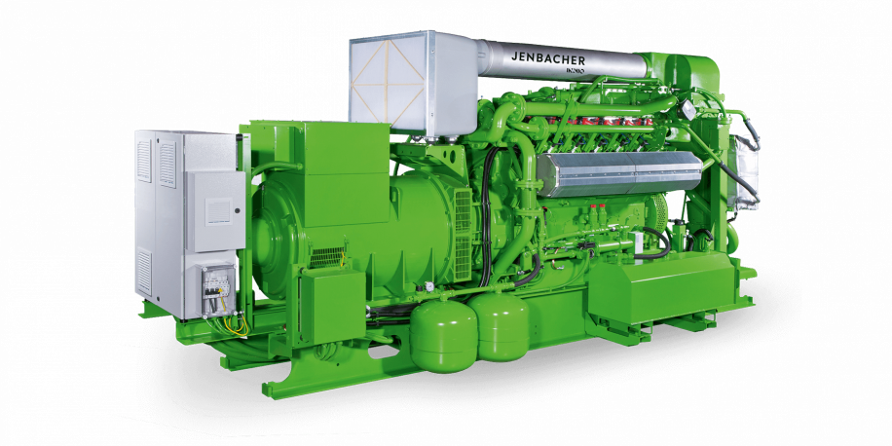

JENBACHER TYPE 3

Technical maturity and a high degree of reliability make INNIO’s Jenbacher Type 3 gas engines a leader in their range. Long service intervals, a maintenance-friendly engine design, and low fuel consumption ensure maximum efficiency, while enhanced components prolong service life—even when employing non-pipeline gases such as landfill gas.

Jenbacher Type 3 engines offer proven savings on service and fuel consumption, giving customers excellent efficiency.

- Two-stage mixture cooling allows for high flexibility

- Turbocharger bypass evens out extreme operating conditions

- LEANOX* lean burn control ensures minimal emissions

- Application A range of applicable gas types increases efficiency levels and reduces industrial emissions. Gas types include:

- Natural Gas

- Associated Petroleum Gas (Flare Gas)

- Propane

- Biogas

- Sewage gas

- Landfill gas

- Coal mine gas

- Other special gases (e.g., coke, wood, and pyrolysis gases)

JENBACHER TYPE 4

Based on the proven design concepts of Jenbacher Type 3 and Type 6 engines, Type 4 gas engines are characterized by high power density and outstanding efficiency. Enhanced control and monitoring provide easy maintenance capabilities, as well as excellent reliability and availability.

Jenbacher Type 4 engines have the same design, emissions control, and waste gas-to-energy capabilities as their Type 2 and Type 3 counterparts, plus high-power density and outstanding efficiency in their power range.

- The high-power turbocharger allows for optimal operation at higher air intake temperatures and altitudes.

- The four-valve cylinder head features enhanced swirl and channel geometry using advanced calculation and simulation methods, resulting in optimal cooling and combustion conditions.

- The Type 4’s crack connecting rod reduces bearing wear and is easy to maintain.

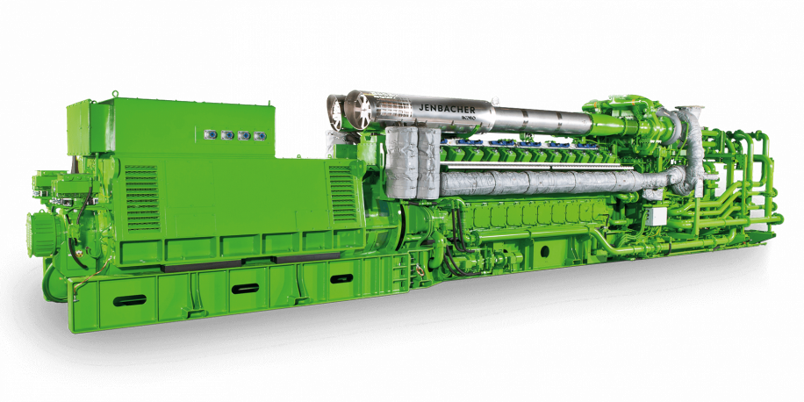

JENBACHER TYPE 6

The result of continuous enhancements and extensive experience, INNIO’s Jenbacher Type 6 gas engines are an advanced and reliable addition to its product line. The 1,500-rpm engine speed results in a high-power density with low installation costs, and its pre-combustion chamber achieves high efficiency with low emissions.

Type 6 engines are loaded with features that enhance heat recovery, assure stable combustion, reduce emissions, and increase efficiency—taking the Jenbacher line to new levels of performance.

- A centrally-located purged pre-combustion chamber helps provide optimal ignition conditions.

- The spark plug ignition energy is amplified in the pre-combustion chamber, facilitating stable and reliable combustion.

- Miller valve timing reduces the compression temperature and increases the safety margin to knocking limits, providing improved ignition timing and high efficiency.

JENBACHER TYPE J624

The world’s first two-stage turbocharged gas engine, INNIO’s Jenbacher J624 provides a new level of engineering excellence. The J624 offers significant advantages, particularly in the area of multiple engine power plants for independent power generation and combined heat and power (CHP) solutions.

While all gas engine applications work well with the fuel flexible turbocharged J624 engine, there are two areas where you’ll find it excels – large power generation projects, including multiple engines, and CHP or cogeneration solutions – making the J624 more economically practical than gas engines with single-stage turbocharging.

- Two-stage turbocharging increases power density by 10%

- 4.4 MW electrical output is achieved at 1,500 rpm

- Capable of up to 90% total efficiency

- Maintains full output at high ambient temperatures and altitude

- Low specific fuel consumption reduces operating costs

- Flexible and modular design promotes ease of transportation and installation

- 5-minute start-up time

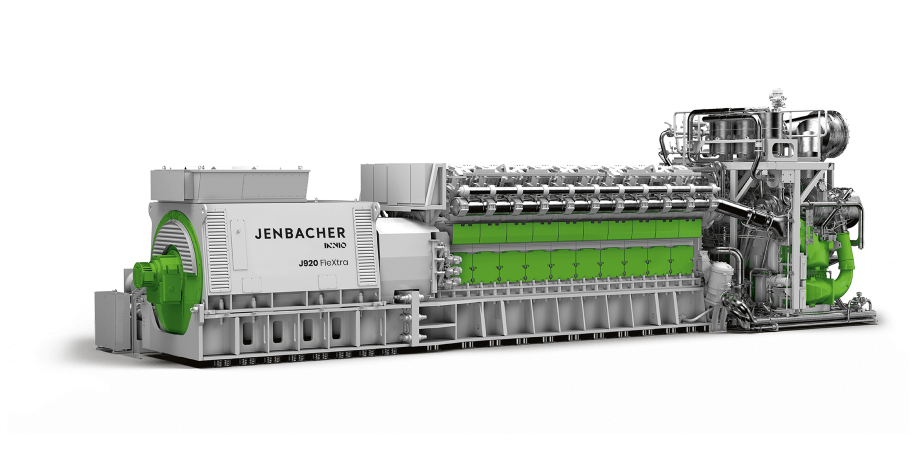

JENBACHER TYPE J920

Whether you’re seeking full power at high-efficiency levels or a unit capable of a start-up in less than 3 minutes, INNIO’s Jenbacher J920 Flextra gas engine is a reliable solution for large gas engine power generation plants. This Jenbacher gas engine is designed to support a broad variety of multiple-engine power plant solutions–from remote power supply to combined heat and power (CHP) generation.

The newest and largest Jenbacher gas engine has, at 49.9%, the highest electrical efficiency of any Jenbacher gas engine.

- A smaller carbon footprint and more energy efficiency

- High power density at low investment costs

- Stable power output and reliable efficiency in any ambient condition

- Quick startup for grid stabilization and easy maintainability